2.1.2.2 Digital Servo

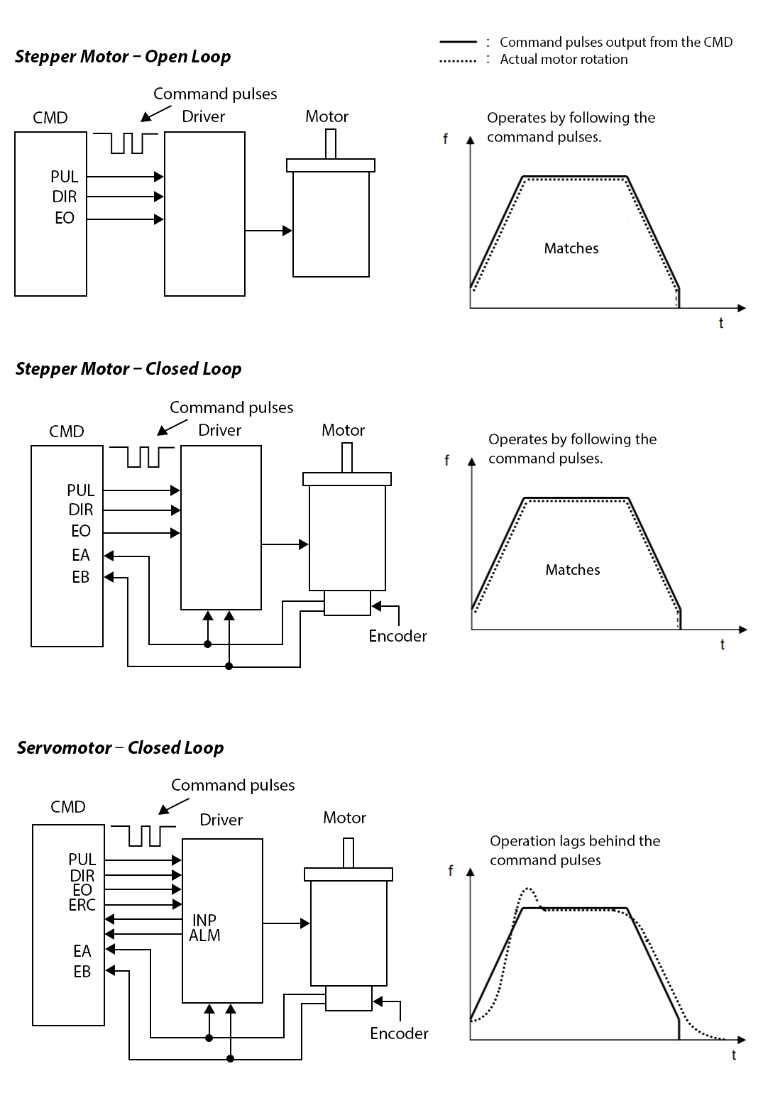

The servomotor rotation lags behind the command pulses from the Commander core. This means that when the Commander core completes outputting pulses, the encoder will take some time to return all of the pulses. As such, there is a need for more communication between the Commander core and the servo drive. A servomotor driver will need the pulse (speed command), direction (direction command), enable, INP (in-position), ERC (deflection counter clear) and ALM (alarm) connected. It is also strongly recommended to connect the encoder output to the Commander core.

The servomotor rotation lags behind the command pulses from the Commander core. This means that when the Commander core completes outputting pulses, the encoder will take some time to return all of the pulses. As such, there is a need for more communication between the Commander core and the servo drive. A servomotor driver will need the pulse (speed command), direction (direction command), enable, INP (in-position), ERC (deflection counter clear) and ALM (alarm) connected. It is also strongly recommended to connect the encoder output to the Commander core.

The servomotor driver will send:

An INP (in-position) signal is sent from the driver when the motor has reached the requested position based on the pulses sent. The polarity of this input is set with the POL[axis](Bit7). When the INP[axis] function is enabled, the operation completion status is delayed until the in-position signal is received from the driver.

An ALM (alarm) signal is received when there is an error or abnormality in the servo driver or motor. This can include:

- The deflection amount becomes abnormally large.

- Excess current is flowing through the motor (instantaneous measurement, or at certain intervals)

- There is a temperature error.

- There is a power supply voltage error.

The alarm signal associated with each error varies with the servo driver. Generally, the signal from a servo driver is kept ON until it is cleared. The polarity of this input is set with the POL[axis](Bit5).

As such the ERC command can be set up so the Commander core can send an ERC (deflection counter clear) signal to clear the error. The polarity of this output is set with the POL[axis](Bit8), while the pulse width is set with the ERCP command and delay is set with the ERCD command.

The figure to the right shows connection examples for a servomotor driver.

|

ASCII |

||||||

|

Standalone |

⎯ |

EO |

⎯ |

⎯ |

⎯ |

⎯ |

< Previous SubSection | Section Home | Home | Next SubSection >