Active Gain Control (AGC) Technology

AGC technology optimizes the drive current in real-time.

In conventional technologies, the motor control drivers generally supply a motor drive current greater than the peak current required by the maximum load to provide sufficient margin for the motor torque. This extra current continuously flows, resulting in excess heat generated on the driver and motor. As an option, a sensor or a microcontroller can monitor the changes in the load conditions, thereby adjusting the motor drive current according to the load conditions. This feedback process requires extremely complicated control. The closed-loop current control system can minimize unnecessary current consumption but adds additional cost.

The CMD-4EX-SA-TBD uses motor driver ICs incorporating AGC technology, which senses a motor's load torque and automatically optimizes the motor drive current. The AGC technology makes it possible to prevent a motor from going out of step while simplifying high-efficiency motor control.

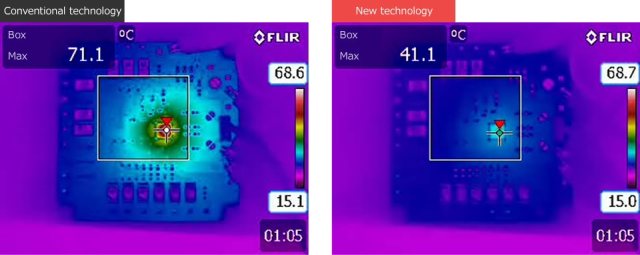

Improving efficiency, saving energy, and significantly reducing heat dissipation in the motor without adding additional cost:

AGC technology automatically adjusts the motor drive current according to a motor's load conditions to reduce extra current, thereby considerably reducing the amount of heat generated by the motor driver IC and the motor. This helps reduce overall heat generation in a system and the resulting degradation.